[Editor’s Note: As perovskite solar cells are connected together to form a solar module, cells that are shaded in the module, such as by a fallen leaf, can be driven into reverse-bias operation by cells with higher current output. A recent study featured on the cover of the journal Joule shows how perovskite solar cells can face additional challenges beyond those of silicon cells and proposes innovative strategies for addressing them.]

Perovskite solar cells are widely regarded as a promising next-generation photovoltaic technology owing to their high energy conversion efficiencies and low-cost potential. But limited stability has impeded commercialisation. While these stability issues are well known under normal operating conditions, experience shows that the most demanding durability issues for fielded modules arise when cells become reverse biased, where even the exceptionally rugged silicon cells can struggle. Important reverse bias challenges facing perovskite solar cells have received very little attention, except in only a limited number of papers that report reverse-bias degradation in cells. Improved understanding and resolution of these reverse-bias effect are necessary for perovskites to become a commercial reality.

Now, appearing this month on the cover of the journal Joule, a team led by Prof. LAN Dongchen from Zhejiang University College of Electrical Engineering and Scientia Prof. Martin Green from UNSW identify additional challenges faced by perovskite solar cells under reverse-bias conditions and propose strategies for addressing them in terms of both cell connections within the module and bypass diode protection.

Figure 1: The August cover of the journal Joule (volume 6, issue 8).

“On the cover: Subdividing cells through an extra laser scribing step provides a simple but generic approach to better protecting thinfilms like perovskites from reverse bias effects, such as that due to shading of a fallen leaf. Image credit: Dongchen Lan and Martin Green.”

Source: Joule 2022.

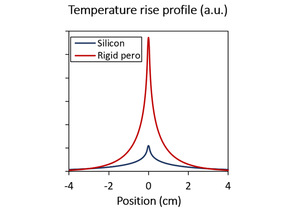

First, perovskites will face more severe heating issues under reverse bias. Silicon is not only far more robust than perovskites but has good lateral thermal conductivity that helps prevent localised heat build-up. For perovskites, besides well-known thermostability issues, cells will attain higher local temperatures due to poorer lateral heat conduction. The temperature rise due to power dissipation through a shunt can be about 5 times higher in a glass-based perovskite module than in silicon one. The situation is even worse in the flexible modules that have been proposed.

Figure 2: Temperature rise in a glass-based perovskite module versus that in a silicon module. Source: Joule 2022.

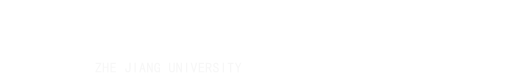

Even more challenging is how to protect perovskite cells from reverse bias, which is particularly damaging to them. A simple, generic approach to better protecting thin-films from reverse bias effects is to subdivide a long-thin cell module into series/parallel connection of smaller cells, which requires just one extra laser scribing step in addition to the standard scribe process. This will control both reverse-bias stresses due to partial shading and the impact of local defects.

Figure 3: Series/parallel cell connection for thin-film modules. Source: Joule 2022.

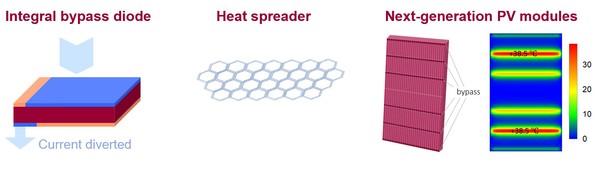

Another approach is to provide bypass protection as for silicon modules but, rather than a bypass diode for every 20 – 24 cells as in this case, one would likely be required across each perovskite cell. This may be possible at low cost by integrating bypass diode into each cell. For the best stress control, horizontal-bypass layout with currents flowing across cell widths, possibly complemented by inlaid heat spreaders and optimal cell lengths determined by thermal diffusion lengths may limit local temperature rises to below 40℃ in the worst situation while protecting the main cell regions, with further improvements being possible.

Figure 4: Integral bypass diode to divert reverse currents for protection of the main cell (left); heat spreader to mitigate local heating (middle); using both measures to contain temperature rises for a commercial scale (2 m×1.2 m) photovoltaic module (right). Source: Joule 2022.

Individual cell protection can also be realized through uniform reverse breakdown if a cell stays stable under such conditions. SunPower has pioneered such individual cell protection in the company’s market leading product although the approaches used are not directly transferrable to perovskites.

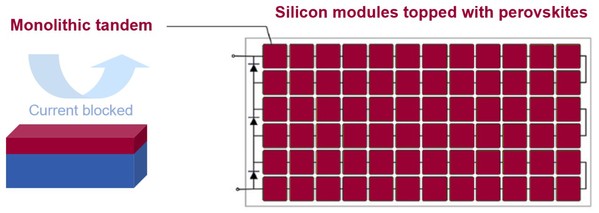

Finally, apart from delivering higher efficiency, the monolithic perovskite/silicon tandem has an additional advantage in containing reverse-bias stresses for perovskite cells. Series-connecting perovskite cells to more robust silicon cells can protect perovskite cells from reverse breakdown. Also, protection of the tandem against large reverse-biases is straightforward because the bypass protection for silicon modules is readily accessible to the monolithic tandems that are virtually silicon modules topped with perovskites. The perovskite cell’s bandgap is advised to be suitably lower to prevent the silicon cell driving the perovskite cell into reverse bias under some conditions.

Figure 5: Monolithic perovskite-silicon tandem structure to enhance the reverse-bias stability (left); silicon modules topped with perovskites that can use conventional bypass diodes (right). Source: adapted from Joule 2022.

Beyond an alternative route towards long-term stability, “stress management can improve the performance and relax stringent requirements upon robustness”, as pointed out by the authors.

Related paper:

D. Lan, M. A. Green, “Combatting temperature and reverse-bias challenges facing perovskite solar cells”, Joule, 6 (2022), DOI: https://doi.org/10.1016/j.joule.2022.06.014